Construction of Database for Flow Control

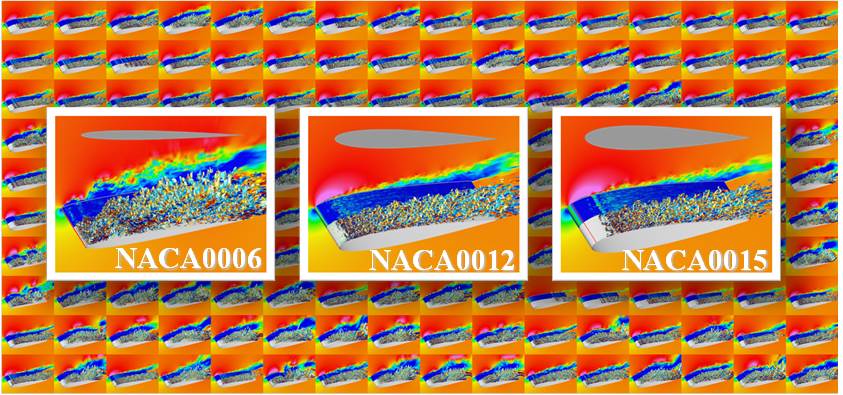

We have carried out a massive parametric study of flow control simulations around airfoils for over 200 cases on a small scale (low Reynolds number) problems by using the K computer. The effects of the design parameters of the DBD plasma actuator on aerodynamic characteristics have been investigated, and an efficient control guideline has been clarified. The database obtained from the parametric study will form the basis of the “design innovation” in the concept of “aerodynamic design by the dynamic allocation of microdevices.”

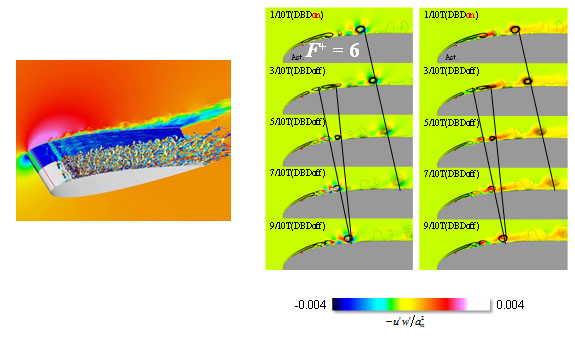

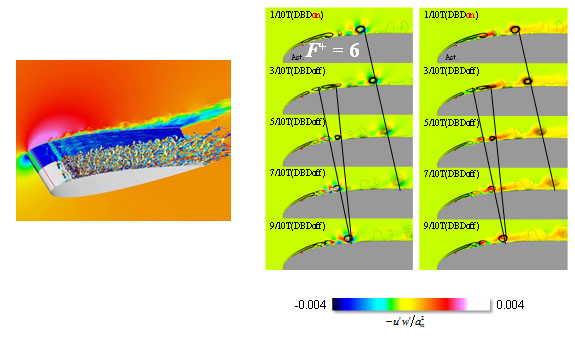

Massive parametric study of flow control simulation

Further Investigation of Flow Control Mechanism

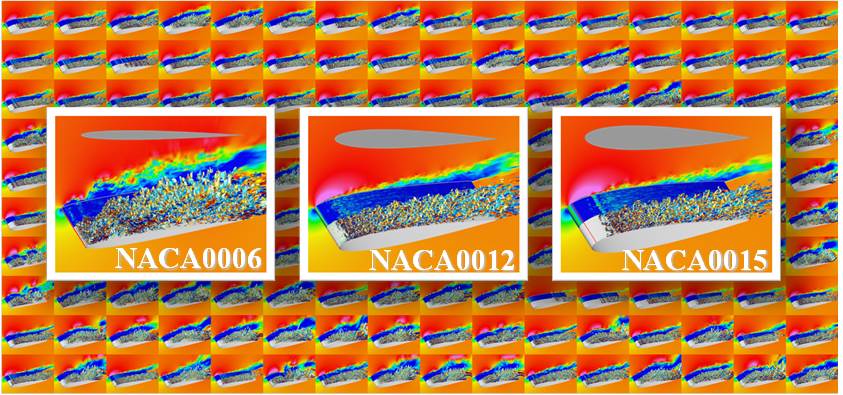

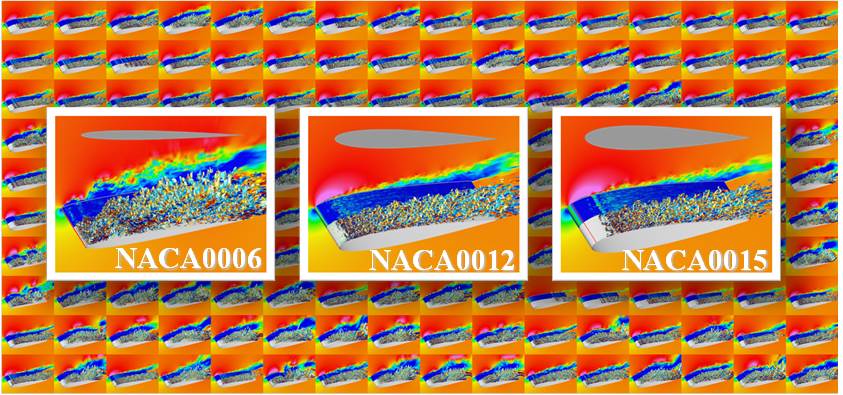

Further investigation has been carried out for typical cases of the flow control simulations around the airfoil on a small scale (low Reynolds number). On this scale, turbulent transition is important, and plasma actuation, which promotes turbulent transition, has been found to be important. This important conclusion will lead to improvement of the efficiency of the flow control.

Fig: Instantaneous flow structures over the wing at the Reynolds number of O(104) with the DBD plasma actuator

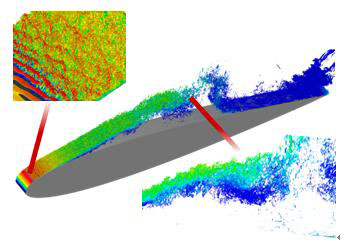

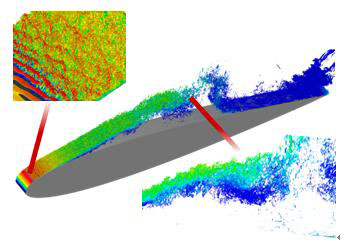

Effects of scale of fluid machineries on flow control

There exist a large number of fluid machineries of different scales (i.e., velocity and size). The scale influences to the efficient flow control method. Therefore, we have investigated the scale effects on the flow field characteristics by the flow control simulations on several scales. These simulations require large-scale computations, which can be conducted only with a K computer. Figure shows the instantaneous flow structures around the airfoil at a high Reynolds number without flow control. Flow control simulations around the wing at the intermediate and large scales (medium and high Reynolds numbers) are ongoing, and the effects of the scale on flow control characteristics are gradually being understood.

Fig: Instantaneous flow structures around the wing at the Reynolds number O(106)

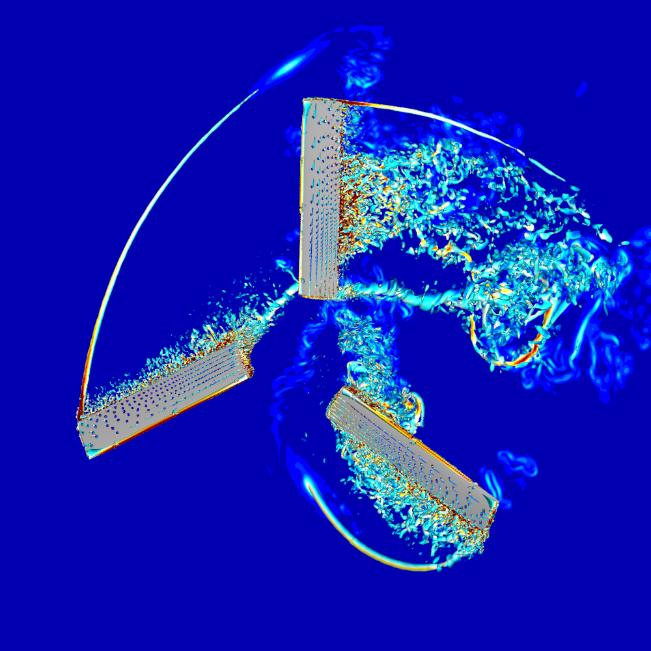

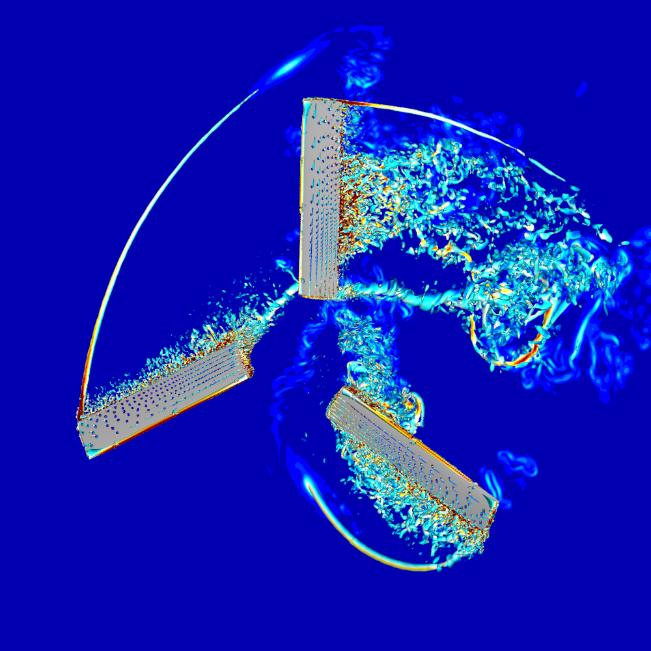

Flow control simulations over fluid machinery

We have started flow control simulations of actual fluid machinery, which shows the applicability of the flow control devices and technologies established in this project. The flow control simulations of wind turbines at the small and intermediate scales are currently among the main targets of this project. Figure shows a snapshot of the instantaneous flow fields around the wind turbine model without flow control. Flow control simulations will be conducted for this baseline case to demonstrate how to control three-dimensional flow separation using the plasma actuator, as well as the extent to which the DBD plasma actuator can improve the performance of the wind turbine model. Additionally, the combination with feedback loop control is considered to realize more efficient flow control and to improve the DBD plasma actuator flow control performance.

Fig: Instantaneous flow fields around the wind turbine model without flow control devices